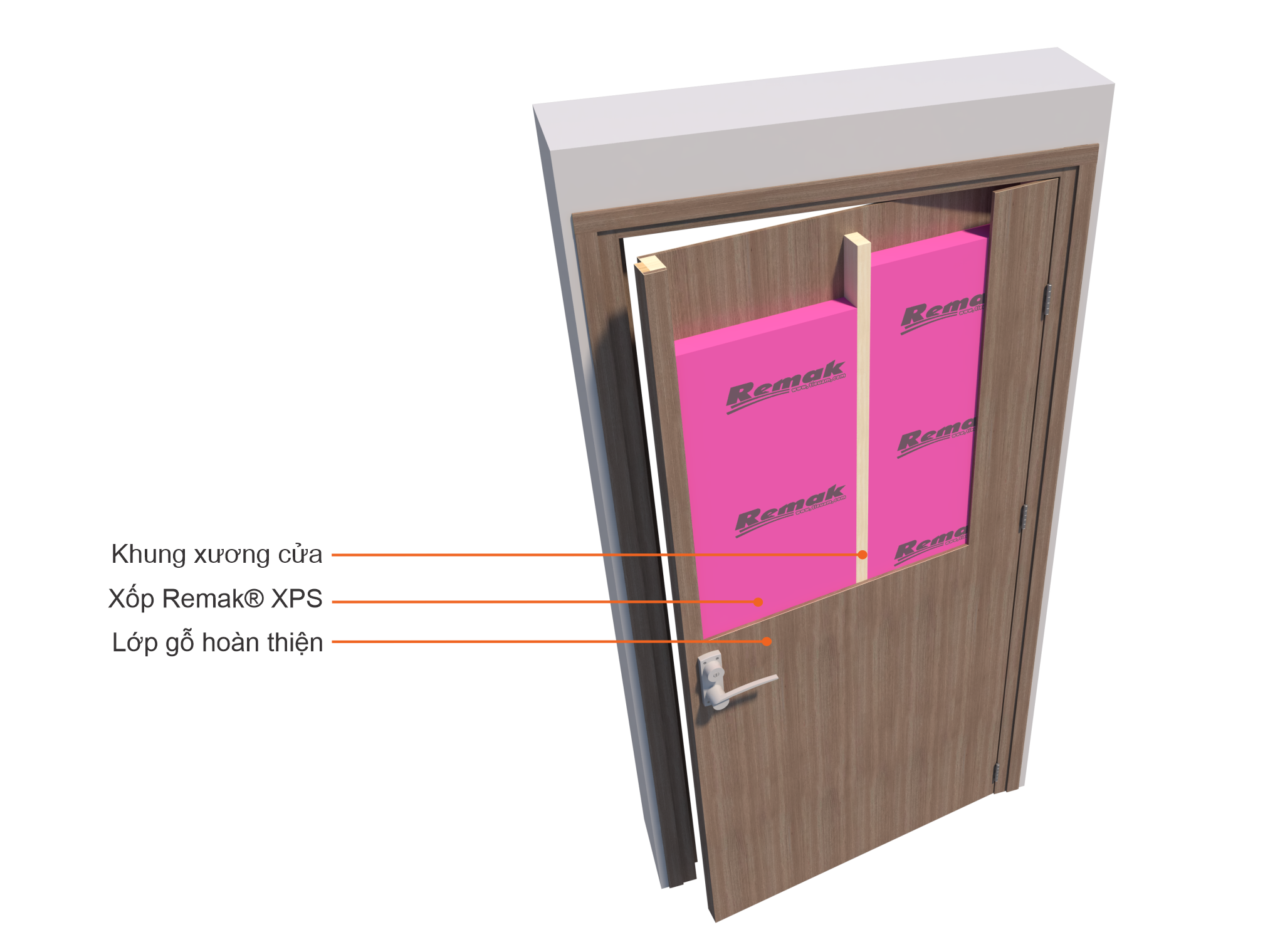

Remak® XPS - Solution for Flame Retardant Soundproof Door Core

Ultra-light extruded Remak® XPS, which has a particularly close-cell molecular structure, is made from food-grade CO2 (which replaces traditional gas) on an advanced production line. The material then becomes a suitable candidate for replacing common materials used in making the core layer for heat and sound insulation doors.

DESCRIPTION

Remak® XPS foam can be used as a soundproof door core to remove unwanted noise from outside and inside the room. This foam is an effective soundproofing material, capable of reducing vibration and noise.

Benefits of using Remak® XPS for door core:

Effective sound insulation: Remak® XPS foam has good sound insulation, minimizes outside noise from entering the room. These improves innovative boards improve the room acoustics and creates a quieter and more comfortable space.

Excellent thermal resistance: With a low thermal conductivity less than 0.028W/m.K, our XPS insulation foam has a good thermal insulation ability. It helps regulate the room temperature. This mean it can prevent heat from entering a room in the summer, and hold heat inside the room during winter, reducing energy consumption and helping to save on air conditioning costs.

Hight durability: Hight compressive strength, moisture resistant features of our extruded polystyrene XPS foam boards make it durable and long-lasting. It can maintain its shape and sustained thermal performance for a long time without deformation or damage.

Litghtweight and easy to install: XPS foam is lightweight, easy to carry and install. You can quickly cut it into specific shapes and sizes on the istallation spot.

Water resistance: Structured by closed cells, our XPS insulation board has excellent water resistance. It can prevent water penetration into the door core, keeping it dry and more durable for a long time.

Dimensional stability: XPS insulation board is less prone to expand or shrink over time, so it can maintain durability and soundproof performance for ages.

Advantages

Building's lifespan increasing

Remak® XPS protects buildings from extreme weather, thereby increasing the lifespan of buildings.

Excellent Thermal Insulation

With an impressive thermal conductivity 0.027W/mK, our Remak® XPS foams are ideal for insulation projects.

Convenient for Site Construction

Our XPS boards are light for easy installing without affecting the bearing capacity of the structure, and can be cut on site for quick construction.

Durability

The stability of polystyrene gives our Remak® XPS a longer lifespan, making it usable for more than 30 years.

Good Sound Insulation Effect

Remak® XPS with a closed cell structure is a soundproof material and capable of reducing noise transmission.

Recyclability

Remak® XPS is 100% recyclable. It is used for circular construction projects and can be reused in our XPS production process instead of being released into the environment.

Great Moisture Resistance

Our XPS insulation foams' closed cell structure ensure low water absorption and high moisture resistance

Reliable Flame Retardation

Our XPS boards are compliant with B1 flame standards, reduce fire hazards and ensure fire safety in constructions.

No Mildew

Remak® XPS does not absorb moisture, so it does not present a favorable environment for mold and bacteria to grow.

Technical Specifications

-

Compressive strength: (ASTM D1621 hoặc ISO 844:2014) 150 - 350kPa

-

Flexural strength: (ASTM C230 hoặc ISO 1209-1:2007) 180 - 400kPa

-

Sound insulation coefficient: (ISO 10534 - 2:1998) Max 80dB

-

Thermal conductivity coefficient: (ASTM 518) Min 0,038 W/m.k

-

Linear shrinkage: (ASTM D2126) Max 1,7%

-

Water absorption: (ASTM D272 hoặc ISO 2896:2001) Max 0,65%/V

-

Fire resistance: (ASTM E84)

Class B1

RESOURCES

Door Insulation Products

Remak® XPS Ultralight 150

Remak® XPS Ultralight 200

Remak® XPS Ultralight 250

Remak® XPS Ultralight 300

Remak® XPS FireOFF 200

Remak® XPS FireOFF 250

Remak® XPS FireOFF 300

Remak® XPS Frozen 200

Remak® XPS Frozen 250