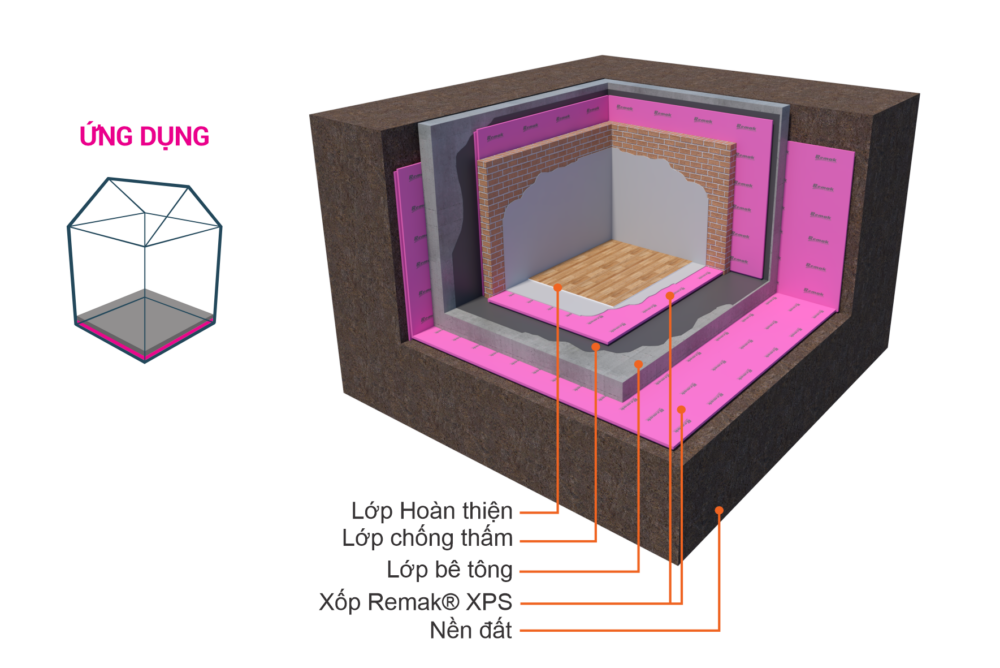

HEAT INSULATION AND MOISTURE RESISTANCE FOR BASEMENT AND CELLAR

Heat insulation for basements and cellars using lightweight advanced Remak® XPS foam is a perfect solution that helps minimize heat conduction and maintain a stabilized temperature. Therefore, the temperature inside and outside does not differ much which causes less mildew phenomenon on the surface.

DESCRIPTION

Basements and cellars often have the common characteristic that they are easily affected by temperature, humidity, and water vapor. Stable temperature control, and maintaining a suitable level of humidity are the most important requirements, directly related to the preservation and quality assurance of stored goods in these works.

Built underground, partly or more than one-half of theirs height below curb level, so heavy rains can cause water to take over your basement or cellar quickly , or ground water leaking into through the wall, floor, and ceiling structures. Meanwhile, the heat conduction and heat loss inside the basement lead to moisture and condensation with an unpleasant moldy smell.

Using Remak® XPS foam for basement insulation is a popular nowadays. Remak® XPS insulation foams are used to insulate basements because of their excellent properties, such as good heat insulation, waterproofing, minimizing the loss of heat and moisture from the outside environment into the basement.

Advantages

Building's lifespan increasing

Remak® XPS protects buildings from extreme weather, thereby increasing the lifespan of buildings.

Excellent Thermal Insulation

With an impressive thermal conductivity 0.027W/mK, our Remak® XPS foams are ideal for insulation projects.

Convenient for Site Construction

Our XPS boards are light for easy installing without affecting the bearing capacity of the structure, and can be cut on site for quick construction.

Durability

The stability of polystyrene gives our Remak® XPS a longer lifespan, making it usable for more than 30 years.

Good Sound Insulation Effect

Remak® XPS with a closed cell structure is a soundproof material and capable of reducing noise transmission.

Recyclability

Remak® XPS is 100% recyclable. It is used for circular construction projects and can be reused in our XPS production process instead of being released into the environment.

Great Moisture Resistance

Our XPS insulation foams' closed cell structure ensure low water absorption and high moisture resistance

Reliable Flame Retardation

Our XPS boards are compliant with B1 flame standards, reduce fire hazards and ensure fire safety in constructions.

No Mildew

Remak® XPS does not absorb moisture, so it does not present a favorable environment for mold and bacteria to grow.

Technical Specifications

-

Compressive strength: (ASTM D1621 hoặc ISO 844:2014) Min 550kPa

-

Flexural strength: (ASTM C230 hoặc ISO 1209-1:2007) Min 800kPa

-

Sound insulation coefficient: (ISO 10534 - 2:1998) Max 80dB

-

Thermal conductivity coefficient: (ASTM 518) Min 0,038W/m.k

-

Linear shrinkage: (ASTM D2126) Max 2%

-

Water absorption: (ASTM D272 hoặc ISO 2896:2001) Max 0,65%/V

-

Fire resistance: (ASTM E84) Class B1

RESOURCES

Basements and cellars Insulation Products

Remak® XPS Heavyload 600

Remak® XPS Heavyload 800