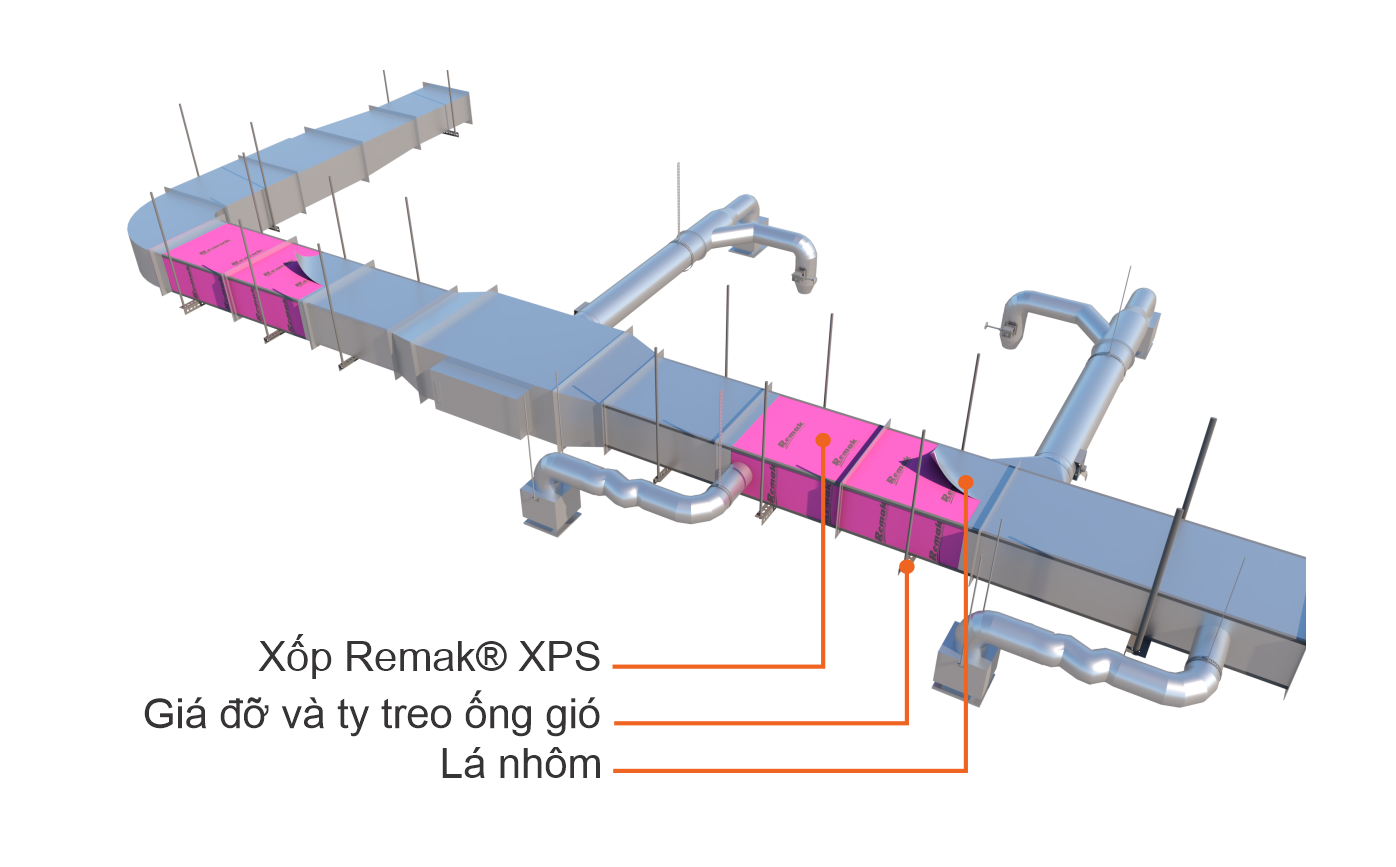

HEAT INSULATION SOLUTION FOR AIR DUCTS

Remak® XPS’s extremely closed-cell molecular structure make it prevent water & moisture, air or sound penetration, minimize dew condensation. This is the perfect heat insulation material and the preferred material in the ventilations manufacturing industry.

DESCRIPTION

Air ducts are irreplaceable in modern constructions, especially in places with high population density, or in the metropolis. The main mission of the ventilation system is to filter and deliver and airflow, remove CO2 out of the building and bring in fresh and clean air.

Nowadays, many different insulation materials are used for air ducts on the market. But the most considerable one is ultra-lightweight Remak® XPS foam manufactured with advanced and innovative extrusion technology.

Using XPS foam to insulate ventilation ducts is an effective method to minimize energy loss and reduce noise levels when the system is operating. Remak® XPS is a highly durable insulation material, it means that it is not easily damaged by moisture or chemicals.

Advantages

Building's lifespan increasing

Remak® XPS protects buildings from extreme weather, thereby increasing the lifespan of buildings.

Excellent Thermal Insulation

With an impressive thermal conductivity 0.027W/mK, our Remak® XPS foams are ideal for insulation projects.

Convenient for Site Construction

Our XPS boards are light for easy installing without affecting the bearing capacity of the structure, and can be cut on site for quick construction.

Durability

The stability of polystyrene gives our Remak® XPS a longer lifespan, making it usable for more than 30 years.

Good Sound Insulation Effect

Remak® XPS with a closed cell structure is a soundproof material and capable of reducing noise transmission.

Recyclability

Remak® XPS is 100% recyclable. It is used for circular construction projects and can be reused in our XPS production process instead of being released into the environment.

Great Moisture Resistance

Our XPS insulation foams' closed cell structure ensure low water absorption and high moisture resistance

Reliable Flame Retardation

Our XPS boards are compliant with B1 flame standards, reduce fire hazards and ensure fire safety in constructions.

No Mildew

Remak® XPS does not absorb moisture, so it does not present a favorable environment for mold and bacteria to grow.

Technical Specifications

-

Compressive strength: (ASTM D1621 hoặc ISO 844:2014) 150 - 350kPa

-

Flexural strength: (ASTM C230 hoặc ISO 1209-1:2007) 180 - 400kPa

-

Sound insulation coefficient: (ISO 10534 - 2:1998) Max 80dB

-

Thermal conductivity coefficient: (ASTM 518) Min 0,038 W/m.k

-

Linear shrinkage: (ASTM D2126) Max 1,7%

-

Water absorption: (ASTM D272 hoặc ISO 2896:2001) Max 0,65%/V

-

Fire resistance: (ASTM E84) Class B1

RESOURCES

Air duct Insulation Products

Remak® XPS Ultralight 150

Remak® XPS Ultralight 200

Remak® XPS Ultralight 250

Remak® XPS Ultralight 300

Remak® XPS FireOFF 200

Remak® XPS FireOFF 250

Remak® XPS FireOFF 300

Remak® XPS Frozen 200

Remak® XPS Frozen 250