REMAK® XPS

Remak® XPS foam produced by Remak Construction & Interior Joint Stock Company using food-grade CO2 technology on a synchronous and advanced production line is a green solution for all projects that need heat insulation – heat protection, sound insulation – noise reduction, moisture-proof, leak-proof, etc. The coefficient of thermal conductivity, water resistance, compressive strength, and bending strength of Remak® XPS is currently rated as the best in Vietnam market (test results at Vietnam Institute of Building Materials – VIBM, Ministry of Construction in November 2022). Using Remak® XPS always brings quick and sustainable profits to construction investors, contractors, design and construction units… With reasonable prices and large inventory level, we are ready to meet all orders with flexible sales policy and perfect customer care service.

Remak® XPS – breakthrough comes from technology and vision

XPS foam is a material that has become familiar and popular in the construction industry today. This type of foam is often used for construction of heat insulation – heat protection, sound insulation – noise reduction, moisture resistance, leakproof for buildings, construction works, etc.

However, according to scientists, most XPS products on the market are being manufactured using old technology, using HCFC-22 (traditional gas) as an expansion aid in the production line. In the long run, this substance causes negative effects on the ecosystem, depleting the ozone layer. Meanwhile, Remak® XPS foam board produced by Remak Construction & Interior Joint Stock Company applies breakthrough advanced technology: using food-grade CO2 instead of HCFC-22. This is a gas with the purity of more than 99.8%, ensuring no having dust and impurities harmful to human health.

Test results at the Vietnam Institute of Building Materials (VIBM), Ministry of Construction on some currently popular XPS models in the Vietnamese market show that: at the same density, but Remak® XPS has durability, coefficient of thermal conductivity, sound insulation coefficient and moisture resistance are all better than other XPS types. It means that, Remak® XPS achieves Top 1 quality.

In fact, even Remak® XPS has launched since the beginning of 10/2022, it has affirmed its advantages, quickly being used by contractors, investors, design and construction units… for projects.

In particular, Remak is firmly on the way to becoming one of the leading companies in the field of: consulting, design, treating acoustics for civil and industrial constructions; production of soundproofing – heat insulation – cold insulation materials. We aspire to create a Vietnamese brand that shows the intellectual stature and Vietnamese pride in the international arena.

In addition to the success in investing in building a production plant to proactively prepare source goods and control the quality, Remak also invests in research and development of new green, clean and environmentally friendly materials. We are always aware that the sustainable development of the business must go hand in hand with the sustainability of the environment and the community health.

That’s why Remak® XPS foam sheets become the crystallization of modern technology and Remak’s vision: we have always demonstrated a strong commitment to building a sustainable future through innovation in materials and creation in solutions. Remak’s aspiration is to bring meaningful values – material comfort – a greater quality of life to our customers, partners, suppliers, employees as well as the surrounding environment and ecosystem.

Remak® XPS Exceptional Quality

Ultra-light Remak® XPS pink foam is self-produced by Remak using clean Polystyrene resin imported from Korea as the main raw material. The product is manufactured in advanced line using CO2 gas technology for food. In addition, it is synchronous machinery, equipment, modern automatic control system. Extrussion process of foam produces insulation foam sheets with density 28-35-38kg/m3, thickness 25-50mm, size 0.6m x 1,8m.

Remak® XPS currently has 4 product lines: normal, Firesafe, recycled and XPS core MgO soundproof panels.

Because it is manufactured by high-grade materials, applied advanced technology, and rigorously monitoring, the finished product of Remak® XPS achieves perfect quality. Remak® XPS is rated as the best soundproof, heat insulation, moisture-proof, leakproof material on the market today, fully meeting the criteria of a green building material according to international standards.

Besides, Remak® XPS has the outstanding advantage of being very light in weight but durable and highly compressive as well as cost-competitive. Compared with PU insulation, the cost of Remak® XPS panels is half that but has twice the compressive strength. Compared to EPS foam, Remak® XPS foam is 10 times more waterproof.

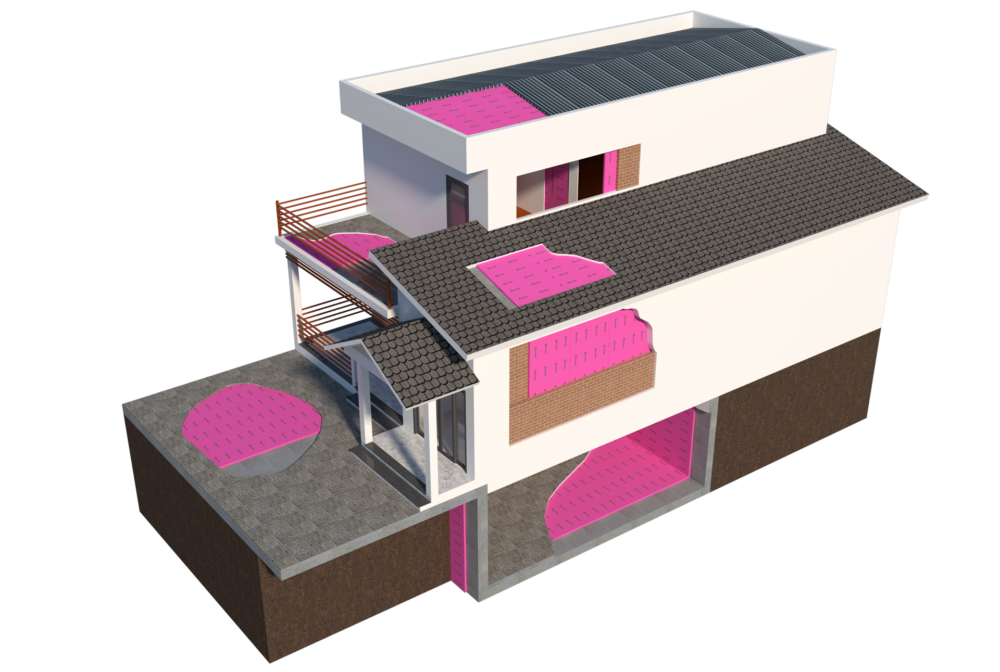

With its outstanding quality, beautiful appearance, ultra-light, Remak® XPS is widely used for different applications of each type of construction as well as in agricultural production, civil, etc.